Those of you who have been following this blog know that I have been spending the last few months engaged in a new photographic series. This series attempts to celebrate the concept of “Made In The USA” as highlighted through the day to day operations of the National Die Company , a small tool and die […]

This next session was spent with Warren, the Quality Assurance person. Quality is very important to the Shop, which is why they were ISO 9001:2008 certified . This certification must be renewed every three years. Annual audits review the Shop’s manufacturing procedures and testing records. Warren says they are dedicated to following the policies, procedures, and customer specifications […]

Today’s session will feature Shipping/Receiving activities. This part of the shop is controlled by John and actually involves two areas: shipping/receiving and a material storage area. The storage area, as the name suggests, is where most of the product material stocks are stored. A variety of raw materials are used during the deep draw manufacturing […]

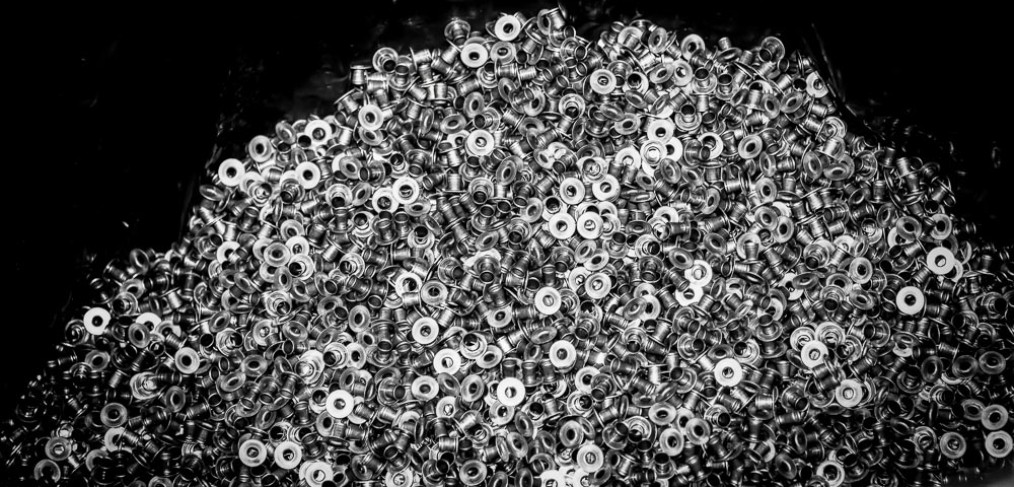

After a conversation I had with Michele, the bookkeeper, and Paul, the president, I decided that I would try to highlight the production of the Shop’s biggest product, the eyelet used in the Ziggity watering systems for chickens. Approximately eight million pieces of this are produced annually for the customer. That means there is at […]

The second session started with a tour of the Tool Room. This is Dave’s room since he is responsible for making any new or replacement punches, dies, or gauges as they wear or break. Here is a sample of what the room looks like. The room is made up of a series of machines used […]